Lyon Bending at the heart of the world’s largest nuclear fusion machine!

20 March 2023

Change of management for Lyon Cintrage Seignobos

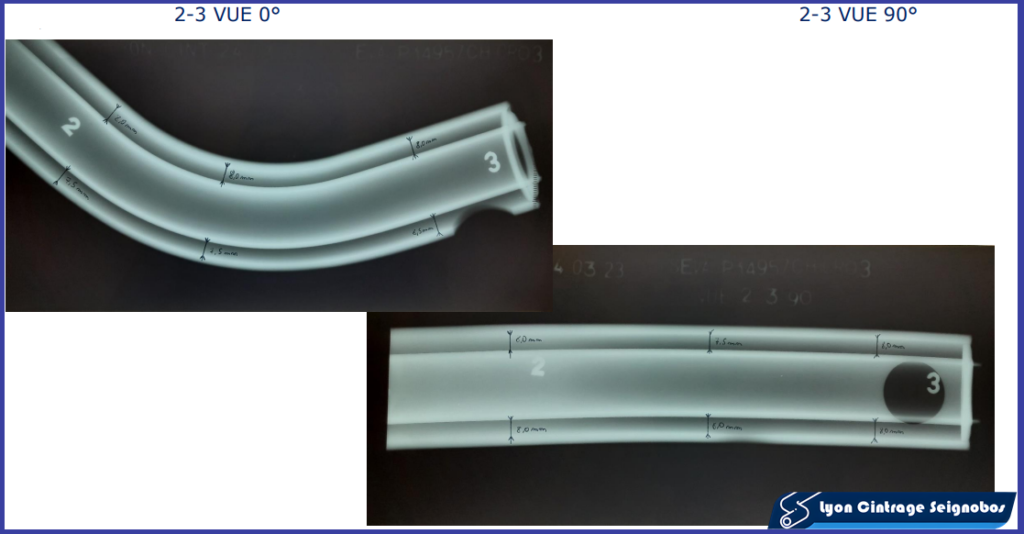

10 April 2024How do you bend 2 coaxial tubes inside each other for a heat exchanger?

To maintain the temperature of an arm above molten glass (1100°C), our customer needed to circulate a coolant through the arm in Ø60.3 OD tubing.

This heat exchanger system cools the outer shell by supplying refrigerant through the Ø33.4 inner tube. A ” double-skin ” or ” double-shell ” solution involving the welding of elbows and half-shells was not an option, due to the stresses exerted on this part.

Lyon Cintrage was asked to find a solution with the following objectives:

- Bending without welding

- 1 mm concentricity / coaxiality requirement met in curved zones

- Ovalization less than 8% on inner tube Ø33.4 and outer tube Ø60.3

The bottom part has been cut with a grinder to show the passage of the inner tube.

Thanks to the implementation of a special process and the dedication of our technicians, Lyon Cintrage was able to meet his requirements and have them validated by X-ray and then by our customer.