Lyon Cintrage celebrates its 100th anniversary!

12 October 2024The nuclear market is doing well, and Lyon Cintrage Seignobos (LCS) is feeling it, with a good number of projects completed in 2024.

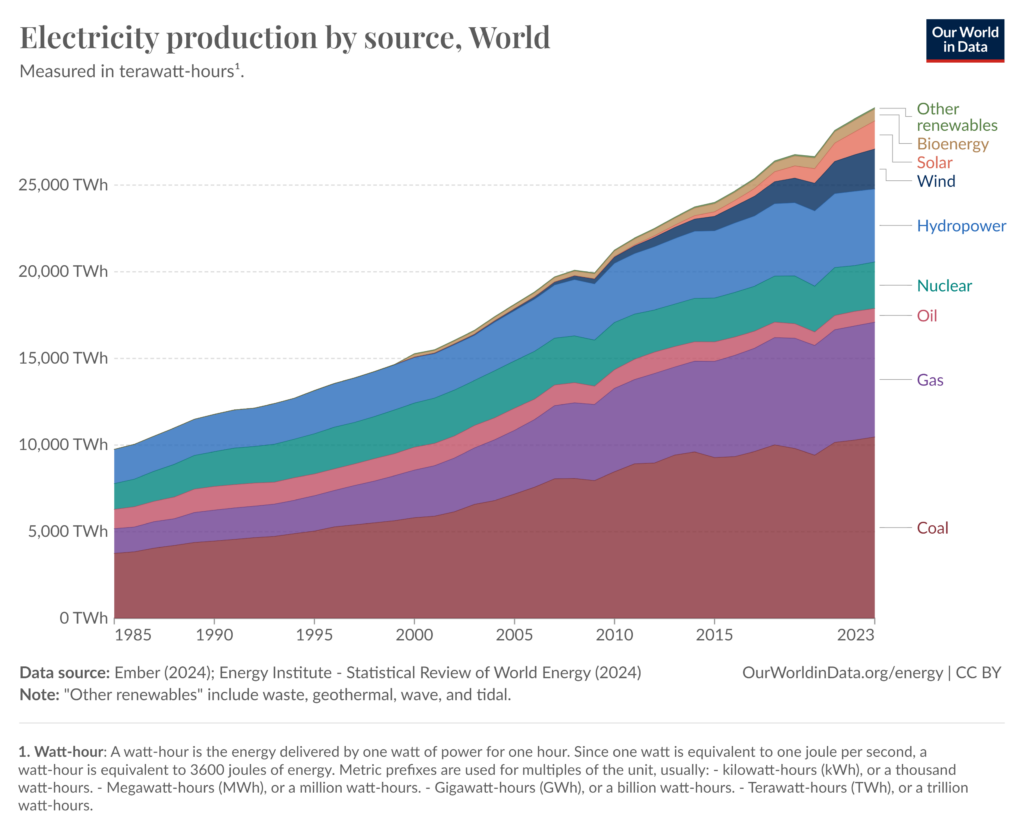

Did you know that if we are to meet our commitments to reduce greenhouse gases and keep global warming below +2°C’ by 2050, global demand for electricity would have to almost double from the current 185,000 TWh to nearly 300,000 TWh? Renewable energies are beginning to develop, but as they cannot be controlled, gas, coal and oil remain the main sources. As a result, many countries, including France, have relaunched their nuclear strategy.

In 2024, Lyon Cintrage will be working on numerous civil and military projects in research, production and fuel enrichment.

Over the years, Lyon Cintrage has developed its expertise in learning and transposing the various industry standards to its trade, such as the famous RCC-M*.

Throughout the project, the various stages follow one another, leading from the front :

- Documentary aspects such as the development of forming procedures for qualification and production.

- Inspections** (destructive or otherwise) carried out in-house or by qualified partners

- Manufacturing operations are often carried out in spaces and equipment dedicated to the nuclear industry to avoid féritic contact***.

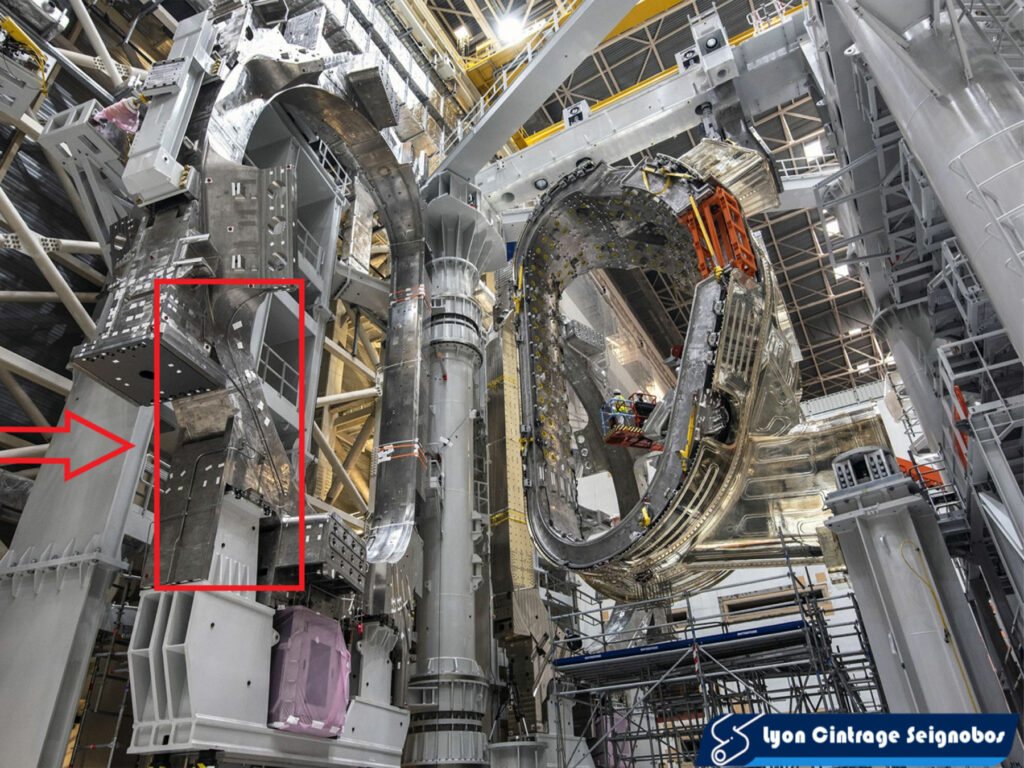

This year, Lyon Cintrage is working on projects as varied as ITER at Cadarache, various CNPEs (Centre Nucléaire de Production d’électricité) operated by EDF, Naval Defense applications, upcoming SMR (Small Modular Reactor) projects and even a Uranium transformation project.

- *RCCM: Ceramic Fuel Reactor with Metal Moderator. The RCC-M is a code developed in France to define the rules for the design, manufacture and inspection of equipment used in nuclear power plants, in particular pressurized water reactors (PWRs).

- *RCC-MN1: Safety-critical components (e.g. reactor vessel, primary piping). These elements have the most stringent requirements.

- *RCC-MN2: Components important to safety, but with slightly less stringent requirements than N1. They include equipment such as secondary piping and systems that play an indirect role in safety.

- *RCC-MN3: Components of lesser importance to safety, but still subject to rigorous standards.

- *RCC-MNC: Unclassified components with standard requirements. (That we never see)

- *RRCC-MRX: for experimental reactors

- ** Thicknesses (cross-sections, ultrasound) Folds & deformations, Ovalization, Mechanical testing, Strength of materials

- ***Feritic contacts generally refer to electrical contacts manufactured or coated with iron-based materials with feritic properties, i.e. magnetic and mechanical characteristics specific to this type of alloy.